Products Description

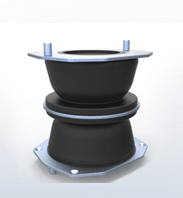

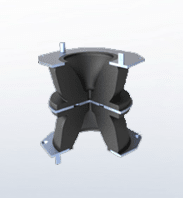

The hourglass spring is made with a top, middle, and bottom rubber partition that is vulcanized as one piece. It is named for its shape which is similar to an hourglass. The product is used as an alternative to the air spring to withstand the weight of the vehicle body and provide soft lateral and longitudinal stiffness.

The hourglass spring is designed with a simple structure, light in weight, and has a large vertical and horizontal displacement. The springs are soft and allow for horizontal rolling of the car body, which makes this spring suitable for railroad tracks with many curves. The hourglass spring's vertical stiffness curve is nonlinear which makes the spring soft during tare load and stiff after tare load.

Compared to the air spring, the hourglass spring requires less space and has a much simpler design, with no need for a height control system. It is lighter, has a larger displacement capacity and lower cost than the air spring.

Advantages

TMT has the capability to simulate load conditions in order to reduce the load stress of the spring through intelligent design, and ultimately reduce load stress during operation. We utilize FEA analysis in order to chose the optimal metal to reduce weight and meet performance requirements. Our structural design, formula, and process solutions maximizes service lifetime, which can be more than 10 years.

Click here to download the product catalogue.