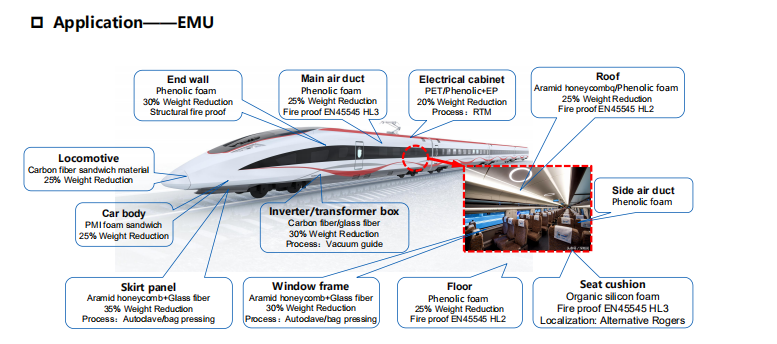

Floor

Product description: The flooring products are installed in the bottom of the car, the upper surface of the car body, generally white or yellow, play a role in carrying and noise reduction. The flooring product adopts the sandwich core structure, where the sandwich layer is phenolic foam material, and the panel is epoxy resin/glass fiber/other fiber materials. TMT's phenolic foam flooring has realized batch application both at home and abroad.

Advantages: Phenolic foam flooring adopts advanced phenolic foam technology, compared with the traditional aluminum honeycomb flooring, there are significant advantages in weight, strength, sound insulation, fire performance: typical 18mm thickness flooring product surface density ≤ 18kg / ㎡, acoustic insulation of more than 28dB, sound insulation amount of more than 28dB, and effectively reduce the noise level of the chassis part of the car; to meet the EN45545-2-HL2 level material fire requirements; meet EN45545-3 E15min structural fire requirements.

Air Duct

Product description: As a kind of fiber-reinforced phenolic foam sheet, duct products are used for ventilation ducts in rail vehicles, playing the role of transmitting air conditioning wind. Air duct is installed on the top of the train, characterized by light weight and noise reduction. TMT has developed different density series of phenolic foam boards for different products and needs.

Advantages: The density of air duct is 75~260kg/m³, which meets the requirements of different grades of lightweight products; the sound insulation of the product reaches more than 18dB, which effectively reduces the noise of the ventilation system. Besides, it meets the requirements of the EU banned substances, as well as the fire protection requirements of the material of EN45545-2 HL3 level.

Center roof panel

Product Description: The center roof panel is installed on the top of the car, which decorates the car and reduces the weight of the car body; it is molded by prepreg and aramid honeycomb core, and the nut block can be buried inside the honeycomb core, which is convenient for installing interface; it adopts molding process, which makes the appearance of the product neat, and the seams are even and consistent, and the installation is more efficient and convenient.

Advantages: Compared with the traditional aluminum honeycomb roof panel, the areal density of fiber reinforced phenolic foam roof panel <4.8kg/㎡, loading practice shows that the actual weight loss reaches 27.1%; thermal insulation effect is more obvious, with thermal conductivity 0.079W/(m.K), there’s no need to use the thermal insulation cotton; sound insulation amount reaches 24dB (8mm thickness); to meet the requirements of the European Union banned substances to meet the EN45545-2 HL2 level material fire protection.

Window Frame

Product description: The window frame is installed in the side wall of the car; using the characteristics of composite material designability, the surface layer and the core layer material layering combination design, using prepreg and sandwich material (aramid honeycomb, PET foam, phenolic foam, strong core felt) integrated molding, we managed to manufacture lightweight side wall window frame.

Advantages: Compared with traditional FRP products, the weight is reduced by more than 25% (areal density as low as 4.5kg/㎡); the sound insulation of the product reaches more than 22dB; it meets the requirements of the EU banned substances, and meets the fire protection requirements of the EN45545-2 HL2 level materials; the flat tensile strength ≥1.6MPa, flat compressive strength ≥2.5MPa, four-point bending strength ≥40MPa, and the peel strength of the drums ≥15(N-mm)/mm.